© 2024 Powered by Antbuildz.com

© 2024 Powered by Antbuildz.com

Safety is always the no.1 priority at every construction site. Not only to the workers on-site but also to the pedestrians or motorists that happen to be at or nearby the job site as well.

Many construction sites are becoming more active at night to accelerate the project schedule. When there is a lack of illuminance, the chances of an accident occurring will increase significantly. The liabilities associated with such accidents are often very high for the project owner. Hence, a lighting tower is essential for providing illumination at night to ensure that work is carried out efficiently and safely.

Lighting towers can also be useful even during the daytime and are used for construction works inside a tunnel or in areas with poor natural lighting. Lighting towers allow workers to complete their tasks more precisely and accurately in conditions with a lack of natural light.

A lighting tower also serves as a great protection to construction sites overnight when no workers are on-site. A well-lit construction site not only deters criminals but also provides an added element of safety for pedestrians and residents nearby the job sites.

Below are a few factors to consider when choosing a lighting tower:

Normally, a lighting tower is attached to a diesel generator (or “genset”) as a power source. But there are also other options which are battery-powered or solar-powered (store solar power generated during the day). Diesel-powered light towers are the best option for job sites without electrical power supply and at remote locations.

If the job site provides easy access to an electrical power source, an electric-only light tower is also a good choice. Diesel lighting tower can be carried out 24 hours without interruption due to the refueling of diesel. The electric-only, battery-powered and solar-powered light towers are much quieter and more environmentally friendly compared to diesel-powered options.

Fuel/battery capacity is especially important for diesel and battery-powered lighting towers for remotely located job sites. These locations may be hard to reach, and it’s highly beneficial and convenient that the lighting towers have a large fuel or battery capacity. This ensures that power outages or any acts of nature do not affect the safety and progress of the job site.

The purpose of a lighting tower is to provide an additional source of light. Hence, the illumination capacity and the rated wattage will always be key considerations. Besides that, you should know the nature of the job site, as well as the activities that require different levels of illumination capacity. It is also very important to position and adjusts the lights correctly to avoid blinding workers or creating glares which can be hazardous for nearby motorists.

The height of the lighting pole is crucial depending on your site requirement. The higher the lighting pole, the bigger the coverage it will be. However, the luminance may also decrease proportionally.

The size of a lighting tower is directly related to its power sources (genset, electrical etc.) and the number and physical size of the light bulbs. The biggest contributor to a diesel-powered lighting tower’s size is its Genset. Only select the right generator size to avoid wet stacking (a condition in diesel engines in which unburned fuel passes on into the exhaust system).

It is also very important to know how big of an area you need to illuminate and the site conditions. Lighting for large open spaces may require lighting towers that offer greater coverage for safety. You will also need to decide: do you require static lighting towers for projects which have longer timeframes or perhaps smaller and compact lighting towers for use at multi-level construction sites so they can be easily mobilized and moved to different locations?

Normally, there are 2 options of lighting towers which are: narrow-body or wide-body. These have to be put into consideration as well as both types have pros and cons especially for the space of work site and access way. A wide-body light tower is more stable and easier to tow because of its low center of gravity, whereas a narrow-body light tower is more compact, but moves around more while being towed to the job site.

After reading the above-mentioned, you should now have a basic knowledge of how and when you need to use a Lighting Tower. To ensure that work is carried out efficiently and safely, lighting towers are essential equipment at job sites for providing illumination in areas with poor natural lighting. They also allow 24/7 operations at construction sites after daytime shifts for improved productivity.

Looking to rent lighting towers and other construction equipment? Visit Antbuildz.com today to check for the best rental rates of all equipment types instantly. You can now Search, Compare, and Rent in just a few clicks. Be it one day only or months, every equipment rental made on Antbuildz.com will be protected with Antbuildz Machinery All Risk Insurance that offers up to S$15,000 first loss coverage. We are the only company in Singapore that covers you with equipment rental insurance, and it’s FREE!

Any Questions?

WhatsApp or Call Us for a FREE consultation on the most suitable equipment for your site. We’re more than happy to assist!

Related Articles

Differences Between Telehandler vs Forklift Rental?

Telehandler vs Forklift Forklifts are one of the most powerful vehicles to lift ...

Learn more

29 Dec , 2024

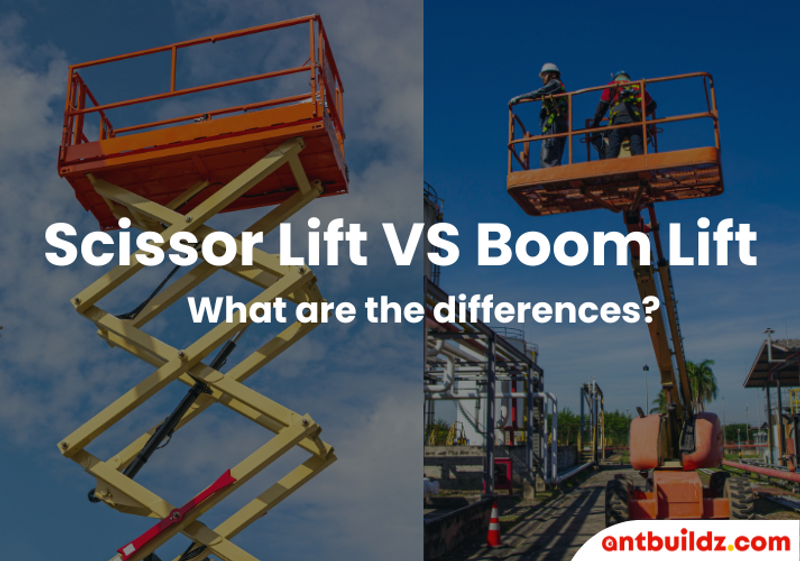

What are the Differences between Scissor Lift and Boom Lift?

When working at heights, safety is paramount. But beyond safety gear and proper ...

Learn more

29 Dec , 2024